Power your research with microfluidics.

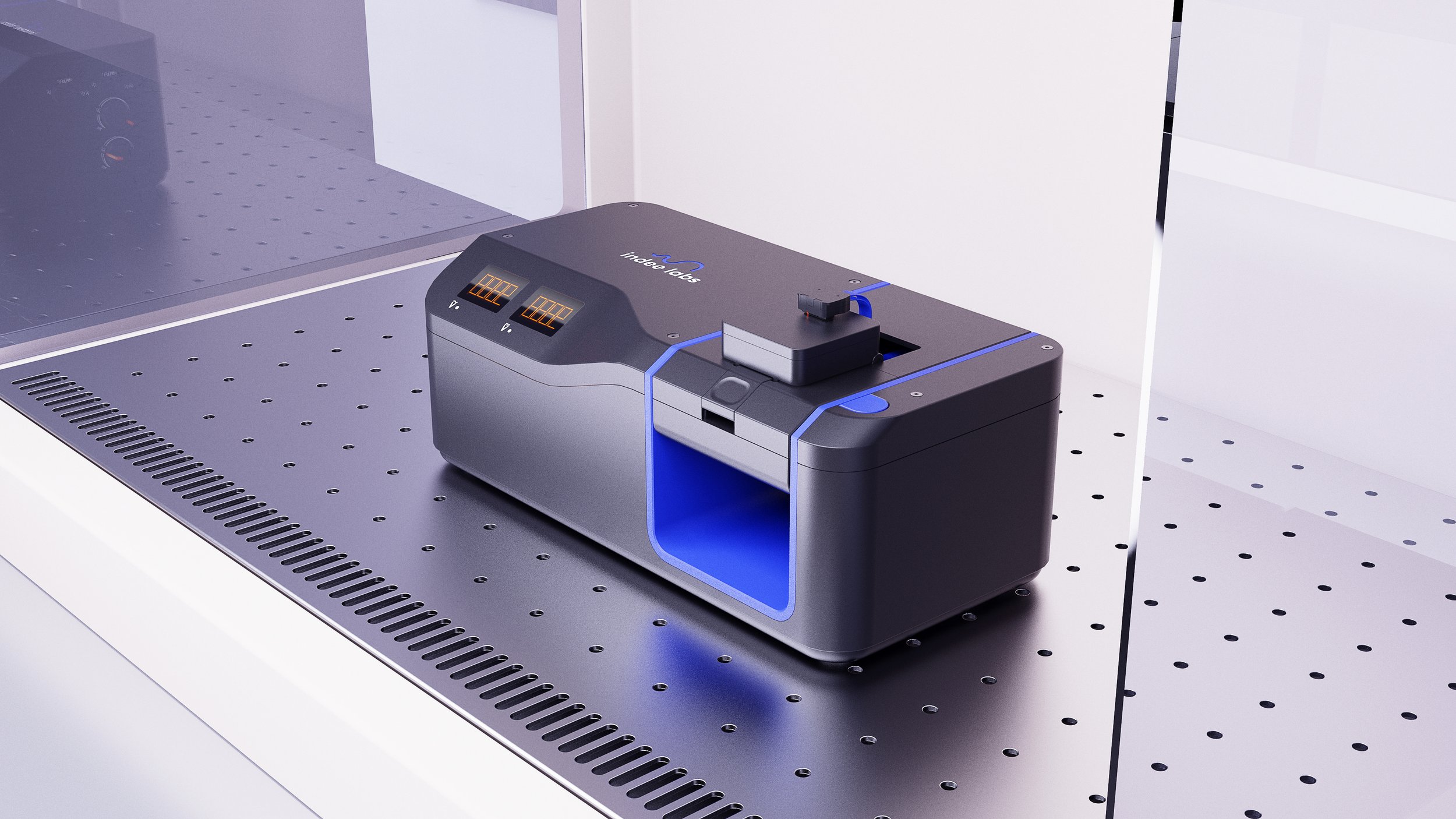

Order Hydropore™ for knockout and knock-in genome editing and join 3 top pharmaceutical companies using the Hydropore™ platform.

Technology

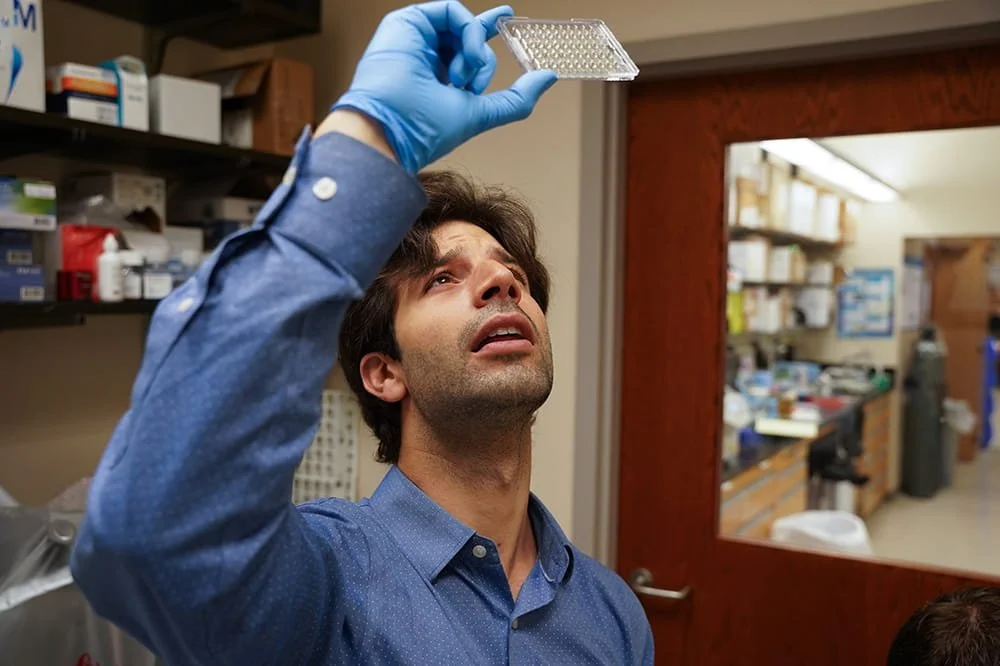

Hydropore™ is a non-viral, platform technology using hydrodynamic conditions termed microfluidic vortex shedding to gently permeabilize cells, allowing for quick and efficient delivery of payloads such as small molecules, DNA, mRNA, and CRISPR Cas9-RNPs into immune cells for gene-editing applications. Our patented technology is a robust alternative to electroporation and viral transduction that addresses current industry challenges in cell therapy manufacturing by relieving the bottleneck of the gene transfer step. Companies can circumvent high development costs, long lead times, and increased risk & regulation while still yielding millions of high-quality, engineered cells with minimal impact on cell viability and function.

Advantages

Preserved Cell Viability & Function — High yield of recovered, viable & modified cells with minimal impact to the native cell state.

High Speed & Throughput Capability — Each 5 x 10mm chip can process >50 million cells at >2-4 million cells per second and as low as 100uL in processing volume.

Simple and Scalable — Easy-to-integrate with existing research, clinical & commercial workflows. μVS devices can be readily manufactured at scales of >2k per day.

Strong Clinical Applicability — Devices are developed in an ISO 13485-compliant manner and all materials in the flow path are medical-grade or USP Class VI implantable-grade.

Order Hydropore™ for knockout and knock-in genome editing now!

Hydropore™ is developed in a regulatory-ready manner and currently available for Research Use Only. A clinical system will be regulated as a tool for biologics manufacturing. Both systems are developed in an ISO 13485-compliant manner and all materials in the flow path are medical-grade or USP Class VI implantable-grade. Hydropore™ systems for high-throughput pooled screening of small volumes.